Manufacturing

The plant is designed so as to allow unidirectional flow of materials and also to avoid cross-contamination.

The building is constructed with Reinforcement Cement Concrete Structure. The production area represents a “building in building” concept. areas have smooth plastered walls . The interfaces of walls, floor and equipment are coved to facilitate cleaning. Partitions and doors are made up of anodized aluminum frames and glasses.

Air handling unit has been provided to all sections in production, quality control & Stores Departments where it is required as per cGMP / WHO guidelines.

Comfortable Man & Material movement provided. Raw Material, Packing Material & Finished Goods entries are Segregated. Entries to individual dept. & Sections are through air locks.

Separate change rooms with proper movement control are provided.

Facility is designed to facilitate effective cleaning & maintenance. Floor is of Kota stone, on top is epoxy coating wherever necessary. Anti fungal treated wall coated with enamel paint for effective cleaning.

All area is having fall sealing & flush type tube fitting. All diffusers & grills are flush to wall & ceiling. All piping & electrical cables are concealed. Coving is provided throughout the plant for effective cleaning.

The windows of manufacturing areas are clean in place glass window vision panels fixed in strong aluminum frameworks are provided to all the departments.

The site includes reception, production unit, Warehouses, Quality control and Assurance, Utilities and maintenance. The manufacturing areas are occupied on first floor. The terrace floor is dedicated to the service area where all the utilities like Air handling systems, Purified Water system are provided. The warehouses are situated in such a way to have a unidirectional flow of material. Warehouses have packing material and finished product store. The Quality Control and QA are on ground floor.

Warehouse

– Raw Material Store (Active, Excipients, Colors & Flavors)

– Solvent Store

– Packing Material Store

– Finished Good Store

Production

GMP model sophisticated equipments are designed for the operation and in view with the area / class in which they are to be installed.

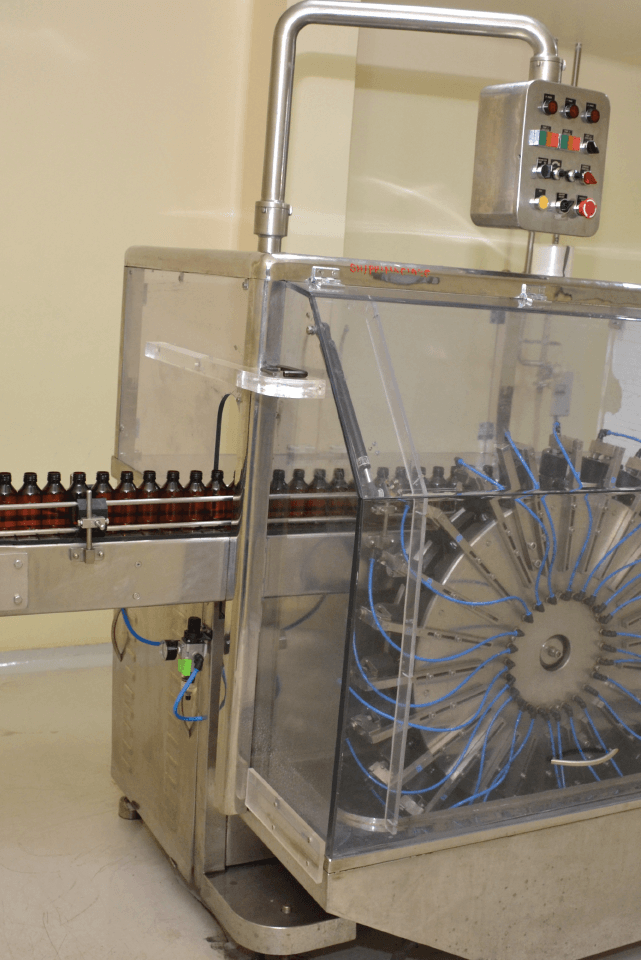

Liquid manufacturing facility is equipped with Sugar Syrup Vessel, manufacturing tank, storage tanks, In line Homogenizer, Filter Press, Water Jet Bottles Washing Machine, Inspection Tables, liquid filling & sealing machine, labeling machine. The equipments are logically installed as per the process steps in order to obtain smooth line operations.

All the equipments are designed and constructed in such a way that the lubricants used will not come in contact with drug product.

| Sr. No | Particulars | Make | Qty. |

| 1 | Sugar Melting Vessel 2200 Litters Gross & 1800 Liters Working Capacity. | Indo German | 1 NO. |

| 2 | Manufacturing Vessel 3600 Litters Gross & 3000 Liters Working Capacity. | Indo German | 1 NO. |

| 3 | In Line Homogenizer | Indo German | 1 NO. |

| 4 | Storage Vessels 3300 Litters Gross & 3000 Liters Working Capacity. | Indo German | 2 NOS. |

| 5 | Horizontal Zero Hold Up filter press (14”x10 plates) with Centrifugal Pump 3000 Liters / Hour. | Indo German | 1 NO. |

| 6 | Transfer Pumps (GMP) for liquid Transfer | Indo German | 2 NOS. |

| 7 | Basket Filter, Zero Hold up with 40-60# basket for Coarse Filtration. | Indo German | 1 NO. |

| 8 | Vibro Sifter GMP Model | Saideep | 1 NO. |

| 9 | Liquid Glucose Transfer pump | — | 1 NO. |

| 10 | S.S Gum Soaking Tank (800 Liters) | Pragati Engg | 1 NO. |

| 11 | SS Jacketed vessel 400 lit. With Stirrer | Pragati | 1 NO. |

| 12 | Water jet bottles cleaning machine | Anchor Mark | 1 NO. |

| 13 | Empty bottles inspection unit | Anchor Mark | 1 NO. |

| 14 | 8heads automatic rotary volumetric Liquid filling & ROPP capping machine ROTOFIL FS120 along with vibratory cap feeding machine. | Anchor Mark | 1 NO. |

| 15 | Inspection Tablet 5’ length | Anchor Mark | 1 NO. |

| 16 | Packing Conveyor Belt 14’ | Anchor Mark | 1 NO. |

| 17 | Box Strapping Machine | Swastik | 2 NOS. |

| 18 | Automatic Sticker Labelling machine With Thermal Inkjet Printer | Maharshi | 1 NO. |

| 19 | Automatic carton overprinting machine with Thermal Inkjet Printer | Maharshi | 1 NO. |

Quality Control

The Quality Control Department consists of separate instrument section, chemical lab, chemical store, hot room, stability study area & control sample storage. Separate areas are provided for storage of control samples and placing of stability chambers. All the drainage in the QC is connected to ETP.

Microbiology laboratory consists of a class 10,000 testing area provided with change rooms & Laminar Air Flow Bench. It also has a general microbiology room with separate areas for media preparation and media destruction.

Microbiology laboratory is well furnished and segregated with critical area, controlled area and general area with respect to the air classification level and criticality of operations. Accordingly the General change room for enter in to the microbiology lab, a dedicated change room for entering into controlled area and Microbiology Assay Room entry change room (2 entry change with entry buffer) and exit change is Provided . UV Cabinet is provided for keeping the linen to be used in Microbiology Assay Room.

A separate wash room & segregated decontamination room is also provided. A separate incubators storage area is also included. Static pass box with Mechanical Interlocks & UV Disinfectants is provided in the media sterilization room.

Throughout the microbiology laboratory pressure differential is balanced to ensure the required airflow pattern for all the critical & control areas.

| Sr. No | Particulars | Make | Qty. |

| 1 | HPLC | Dionex Ultimate 3000 HPLC+ System | 2 NOS. |

| 2 | UV-Visible Spectrophotometer | Shimadzu,UV-1800 | 1 NO. |

| 3 | FTIR-Spectrophotometer | Shimadzu,IRAffinity-1 | 1 NO. |

| 4 | Digital PH meter | DBK, Model 10PHM | 1 NO. |

| 5 | Karl fisher titration apparatus | DBK, Model 10KFT04 | 1 NO. |

| 6 | Polari meter | Rajdhani, Model-RSP-K, STD. | 1 NO. |

| 7 | Melting & boiling point Apparatus | DBK, Model 10MPA03, STD. | 1 NO. |

| 8 | Potentiometric titration equip./VPT-MG | DBK, Model 10PTA12 | 1 NO. |

| 9 | UV cabinet ( 250 mm 365 nm) | Electron, Model EUV-2WR,STD. | 1 NO. |

| 10 | TLC KIT & PLATES | Merck | 1 NO. |

| 11 | Refractometer ( Abbes ) | Rajdhani, Model-RSR-2, STD. | 1 NO. |

| 12 | Vernier caliper digital 6inch | Mutotyo | 2 NOS. |

| 13 | Hot Air Oven | i-therm | 2 NOS. |

| 14 | Incubator | Electron | 3 NOS. |

| 15 | Autoclave | Shreeji | 2 NOS. |

| 16 | Colony Counter | Expo Hi- tech | 1 NO. |

| 17 | Microscope | Micron Optic | 1 NO. |

| 18 | Antibiotic Zone reader | —- | 1 NO. |

| 19 | Potentiometer | DBK | 1 NO. |

| 20 | Conductivity meter | DBK | 1 NO. |

| 21 | Bursting Strength Apparatus | Linux | 1 NO. |

| 22 | Electronic Balance | Essae Teraoka Ltd. | 2 NOS. |

| 23 | Muffle Furnace | i-therm | 1 NO. |

| 24 | Fuming Chamber | DBK | 1 NO. |

| 25 | Hot plate | DBK | 1 NO. |

| 26 | Thermometer | Lutron | 4 NOS. |

| 27 | Hydrolic Press | PG | 1 NO. |

| 28 | Dual pH conductivity meter. | BSR Technology | 1 NO. |

| 29 | Homogenizer | Remi Industries | 1 NO. |

| 30 | Viscometer | Fungi lab. | 1 NO. |

| 31 | Stability Chamber | AD Pharma | 3 NOS. |

Air handling Unit

– Dedicated air handling units have been installed in all core processing areas like the Liquid manufacturing area. The air supplied to manufacturing section is filters through

– HEPA filters. Pressure differential between the core processing areas and the less critical areas like passages is maintained to prevent cross contamination.

– Air handling units of desired CFM is equipped with 10 micron, 3 micron followed by terminal 0.3 micron HEPA filters. 80% return air is collected from rooms and 20% fresh air is added to the system.

– The air temperature is controlled with the help of DX coil.

– In class 100,000 areas is equipped with 10 micron, 3 micron followed by terminal 0.3 micron HEPA Filters. The HVAC system is designed to maintain the required environment conditions.

| LOCATION | AHU NO. | MIN. AIR CHANGE | CLEANLINESS CLASS | AIR FLOW (CFM) |

| Dispensing Booth | LAF 01 AHU 01 | 40 | CLASS 100 (100000) | 800/2.0TR |

| Sampling Booth | LAF 02 AHU 02 | 40 | CLASS 100 (100000) | 700/2.0TR |

| Raw Material Stores. | AHU 09 | 20 | 3 Micron final Filtration | 2300/5.5TR |

| Packing Material Stores. | AHU 11 | 20 | 3 Micron final Filtration | 2500/5.5TR |

| Liquid Manufacturing | AHU 07 | 40 | 100000 | 6100/11TR |

| Liquid Filling | AHU 05 | 40 | 100000 | 1300/4.0TR |

| Bottles Washing | AHU 06 | 40 | 100000 | 1500/4.0TR |

| Labeling & Packing | AHU 04 | 30 | 3 Micron final Filtration | 3700/8.5TR |

| Ground Floor Passage, Quality control, Change Rooms | AHU 08 | 20 | 3 Micron final Filtration | 4000/11TR |

| First Floor Passage, Overprinting, Dispensed Materials Stores. | AHU 10 | 20 | 3 Micron final Filtration | 5700/17TR |

| Microbiology Lab. | AHU 03 | 60 | CLASS 100 (10000) | 1000/2.5TR |

Purified Water System

– Reservoir water is supplied through pipelines by M.I.D.C. to site. Adequate quantities are stored on site in R.C.C. underground and overhead tanks. Raw water is monthly examined chemically and microbiologically and confirmed to be free from pathogens.

– The Raw M.I.D.C Water stored at 30,000 Liters Underground storage tank after chlorination. Underground storage Tank is Epoxy coated from inside & Water is kept circulating by means of hygienic pump. From Underground Tank the water is pumped to overhead sintex Tank as & when needed. From Overhead storage Tank the water is supplied to the pretreatment System consisting of SMBS Doser, UV Steriliser, Duel Media Filter & softener. The soft water so generated is again chlorinated & then stored in soft water tank of 5000liters capacity. The water is then passed through 10 micron and 5 micron filters, water is subjected to Sodium Meta-Bi-Sulphite (SMBS) dosing to remove chlorine followed by Anti-scalant dosing (as applicable). The water is then passed to Two Pass Reverse Osmosis (RO) plant followed by Electro De Ionisation assembly. The product water is collected in 3.0 KL storage jacketed tanks of SS 316L.

– All the purified water storage tanks and loop lines are kept under continuous recirculation at a velocity of above 1.5 m/sec. A slope of 1: 100 is maintained for the water circulation system loop lines.

– The water quality is monitored through on line conductivity meter provided in the return loop line.

– Purified water complies with the requirements as per IP, BP, and USP.Auto dumping valves are provided in the system controlled through PLC Panel activated whenever any parameter crosses the Set limit values.

– The Purified water generation plant is designed for a capacity of 1m3/hr.

– Multi grade filter, Softener and Activated carbon filter are of FRP Vessels. Storage tanks and other lines of complete water system are of SS 316. Re-circulation loops are of SS 316L with electro-polishing.

– Various filters are used at different locations in the water treatment system. Filters are monitored regularly and changed at specific intervals or as on when required.

– Water sampling points and testing frequency after the validation of water system, Microbiology department follow an approved routine Water testing and sampling plan. Water is tested for chemical and microbiological attributes. The test plan involves daily / weekly frequency depending on the type and critical user points.

Utilities

– Oil Free Compressor

– Steam Boiler 400kg/hr

– Cooling Tower

– Sugar Transfer Vacuum System